Suction extraction

to determine technical cleanliness by means of the Particle Suction Separator

Dry extraction method for determining the cleanliness of oversized and/or overweight components:

Examples of large components:

- Empty goods such as trays

- Battery and high-voltage systems

Other possible applications of the Particle Suction Separator:

Active monitoring in production/manufacturing or test environment (VDA19.2)

Advantages of Particle Suction Separator

- No blank value determination necessary, only a new mesh filter (e.g. 20μm Jomesa)

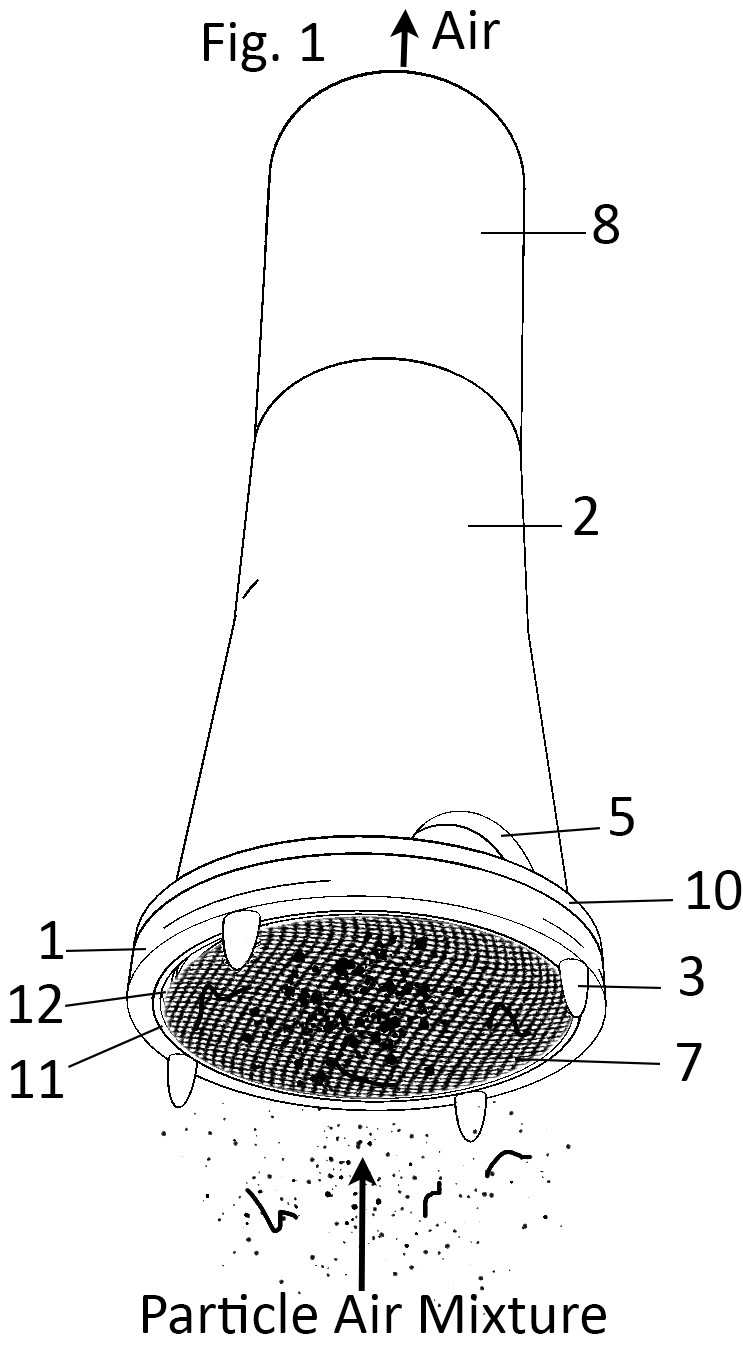

- Direct separation of particles (see Figure 1)

- Partial surfaces of components can be inspected precisely separately

- Large components can be extracted in a targeted manner

- No Wet Extraction On-site use (in-line testing)

- No maintenance of the particle suction separator necessary

- Low training required

- Robot-assisted automation possible

- Reuse of components after extraction

- cost-reducing, economical, time-saving, reliable

- Reproducible results

- logistical effort is very low

- ESD safe material

- can also be implemented in a variable shape according to customer requirements (smaller filter diameter)

Example application video:

Figure 1 shows the operating principle of the Particle Suction Separator:

For utility license support please contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

For analysis support please contact: Diese E-Mail-Adresse ist vor Spambots geschützt! Zur Anzeige muss JavaScript eingeschaltet sein!

Copyright by A Solution (represented by Dipl.-Ing. Alexej Romanenko)

Partikelsaugabscheider / Particle Suction Separator

(Utility Model Protection by the German Patent and Trade Mark Office)

(Gebrauchsmusterschutz durch das Deutsche Patent- und Markenamt)